The Importance of Grounding and Bonding in Volatile Fluid Management

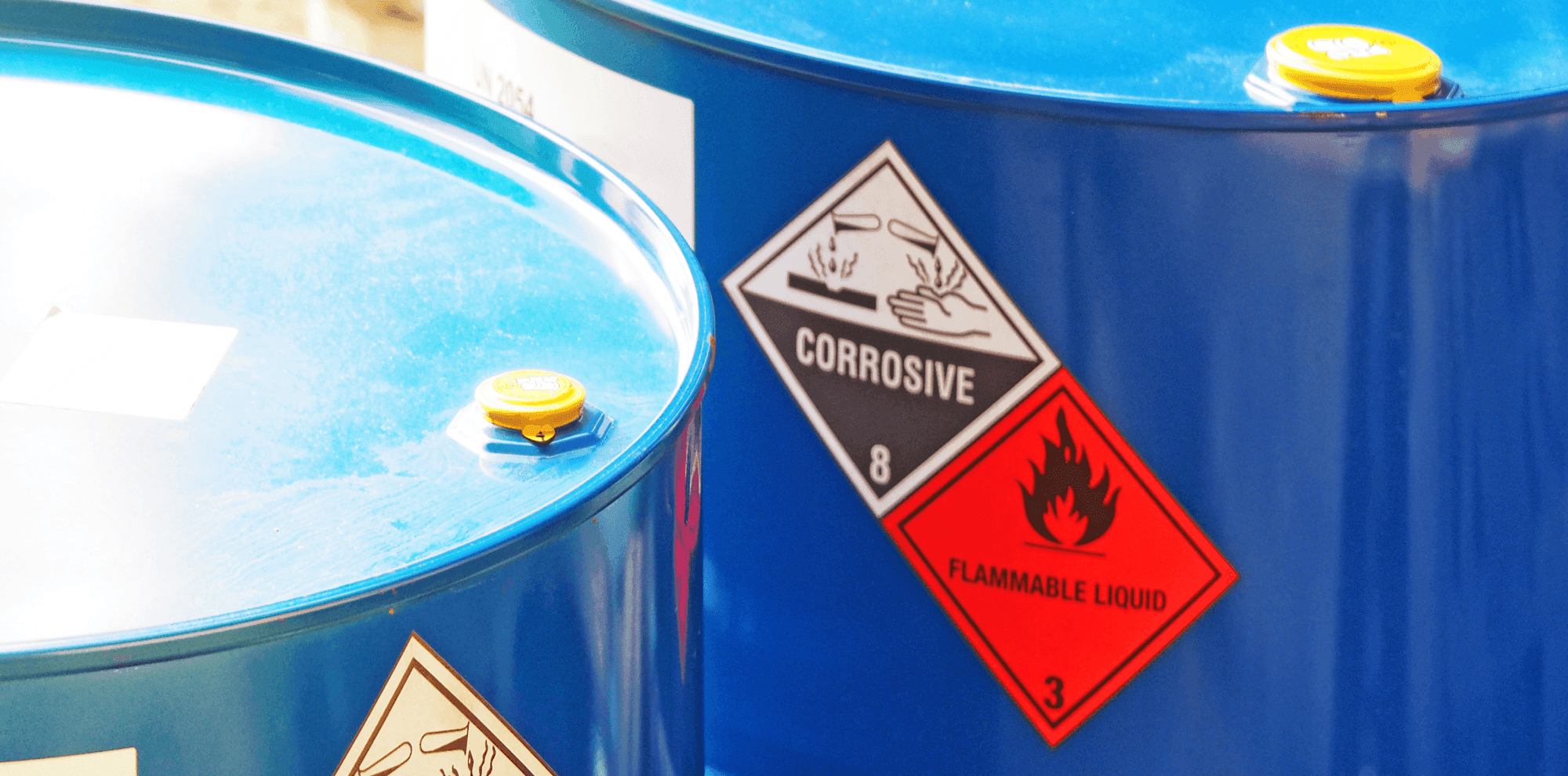

Static electricity builds up when transferring flammable liquids between containers. This buildup can culminate into a spark, with a chance of causing a fire. The combination of grounding and bonding your fluid containers will eliminate any electrical energy buildup. When using our Drip Pans or Drain Pans in a volatile fluid management system, understanding the purpose and difference between grounding and bonding will be vital to creating a safe work environment.

OSHA Regulation in Regards to Grounding

1910.106(e)(6)(ii): Category 1 or 2 flammable liquids, or Category 3 flammable liquids with a flashpoint below 100 F (37.8 C), shall not be dispensed into containers unless the nozzle and container are electrically interconnected. Where the metallic floorplate on which the container stands while filling is electrically connected to the fill stem or where the fill stem is bonded to the container during filling operations by means of a bond wire, the provisions of this section shall be deemed to have been complied with. In summation, you must ground and bond all containers of liquids with a flashpoint of 100 F or less. Note: The flexible nozzle of a Type II safety can is an effective bonding connection.

Bonding

Preventing sparks while transferring volatile fluids starts with bonding the two containers via a metal bonding strap or wire. This bonding will keep both containers at the same electrical potential, meaning no current flow can take place between the two. Alone, bonding will not be enough to eliminate the electric buildup from liquid transfer; bonding will only be able to equalize the buildup between the containers. However, when two containers are properly bonded together, if one container is grounded, the other container will also benefit from the grounding.

Grounding

Simply put, grounding is the connection from an object to the ground, resulting in zero electrical potential. Energy cannot be stored in something that has been grounded to the Earth. Because of this, if two containers are bonded and one of them is grounded, the electrical potential of the grounded container will be zero, and the other container will match that potential. Essentially, any buildup that occurs during liquid transfer will be dissipated into the ground when the containers are grounded and bonded.

These connections are required when flammable fluids are being transferred in any type of work area. Maintaining a metal-to-metal connection between the bonding/grounding wires and the containers is crucial to the efficiency of eliminating electrical potential. That means removing anything other than metal from the connection points (rust, dirt, paint, stickers, etc.). Our Galvanized Drip and Drain Pans would be perfect to use in this type of application.

As for the connections, we also offer Coiled Grounding Cables with Plier Clamps. These Grounding Cables can also be used as Bonding Cables for containers, as long as one of the containers is grounded as well. The coiled cable and clamps are ideal for temporary connections. Be sure to frequently check connections to ensure the safety of volatile fluid management systems.